My Account

Search

Sorry - this product is no longer available

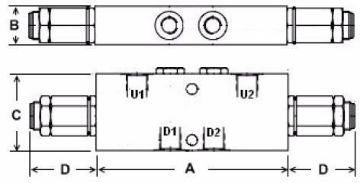

BTM - Multi-Disc Brake -

SKU:

BTM

UOM:

PCS

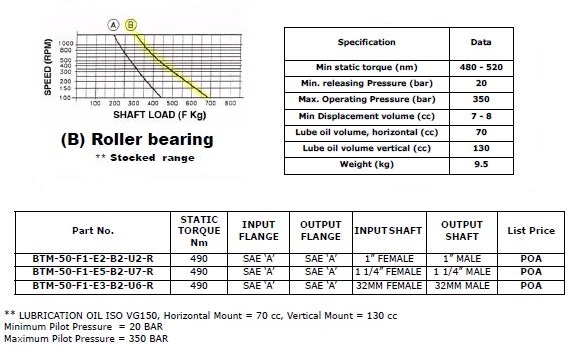

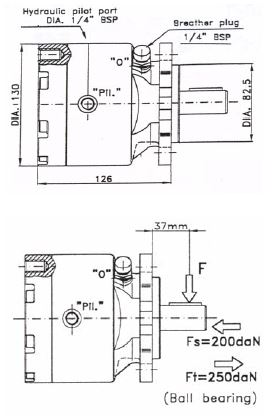

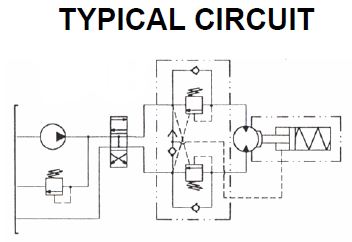

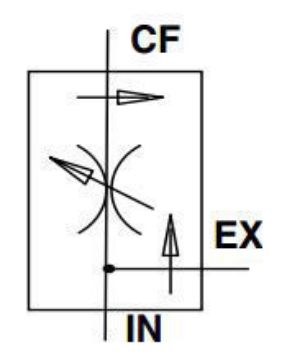

BTM are static brakes which use hydraulic pilot pressure for release.

The braking action is obtained by a series of discs and springs acting onto the main piston.

The brake housing is of spheroidal cast iron and extrusion proof seals are suitable for high pressures.

The BTM brakes are for application on various types of hydraulic motors.

NB: These brakes are only used as a static parking brakes not recommended for dynamic braking applications.

$0.00 inc GST

- *