My Account

Search

Check & Shuttle Valves

SDNR -Check Valve

SDNR Series line mount check valve, available in 5 PSI or 65 PSI cracking pressure. This can also configure in other cracking pressure to meet system requirements. Ports: 1/4" BSPP to 2" BSPP Material: Steel body

$0.00 inc GST

VU - Check Valve

VU- Series line mount check valve, available in 5 PSI cracking pressure (STD). Other spring cracking pressures available on request: suffix C = 14.5psi, L = 65psi, U = 116psi (for sizes 1/2" - 1-1/4"). Ports: 1/4" BSPP to 2" BSPP Material: Steel body

$0.00 inc GST

SBPC - Cross Port Check Valve

These valves are ideally suited for unidirectional motor applications when using a control vlave that has closed work ports in the neutral position. The cross port check valve permits the centrifugal energy of the driven component to dissipate harmlessly. The port centres permit direct fitment via adaptors to Torqmotor® motors or they can be line mounted to suit any motor application. The direction of the check valve can be changed by swapping the end plugs. Applications include rotary hose, rotary brooms, post hole diggers etc.

$0.00 inc GST

SHSV

SHSV Series Shuttle valve in Steel and Aluminuim body Ports: 1/4" BSPP (Steel Body) & 1/2" BSPP 7/8" UNO & 1-1/16" UNO

$0.00 inc GST

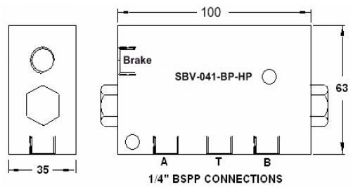

SBV - Brake Release Valve

BRAKE RELEASE VALVE The design of this valve makes it ideally suited for a high pressure brake release circuit. In the neutral position the spring centred spool type shuttle valve directs oil from the brake release system to tank. When pressure is applied to one of the two inlet ports, high pressure oil is directed to the brake release system. Body material - 2011-T6 Aluminium Rated flow - 16L/min. (4 US Gpm) Maximum pressure - 2 to 40 BAR (3500 psi) Shifting pressure - 5.6 BAR (80 psi) Port size - 1/4" BSPP

$0.00 inc GST

Load Sense Signal Conditioners

This load sense signal amplifier is used in those applications where the load sense signal must travel over a long distance. The signal amplifier uses the pump flow to direct the load sense signal back to the pump. When using this device we recommend you also use the signal stabiliser. Part No.: 634503001 -The load sense signal stabiliser is used to stabilise a load sense signal which may be reacting with the pump to create a surging situation in the system.

$0.00 inc GST